Air Compressor Works

Post

Can You Really Manage (Your Air System) Without Measuring?

May 14, 2019

If we didn’t measure production output or bottom-line profit where would we be – probably not in business?

We have been an advocate of measuring using flowmeters the last 20+ years. Prior to 1995 air flow metering has been technically complicated and somewhat expensive. Since then, Air Compressor Works has worked with a flow meter manufacturer to create a simple, effective, inexpensive flow meter for all air system users.

Why would you want to have a flow meter?

- Monitor actual output of your compressor to make sure it is performing correctly so you can take corrective maintenance action.

- Check your air system usage on a day to day basis to make sure that there is not any abnormal increase due to misuse or equipment issues.

- Check leaks when your plant is down to see if there is any increase.

- Determine if a piece of equipment was really using the CFM specified.

- Be able to plan for any future air use by knowing what you are using today.

- Measure your compressed air usage so you can manage it.

We had one customer who after looking at his recordings of the night shifts found that the crew was knocking off 20 minutes early. The meter was not only monitoring air but also indicated what was going on in production – the flow meter was definitely a management tool.

The cost of the flow meter is between $500 and $3,000 and can be paid back in a matter of months as a result of tracking and correcting air system issues.

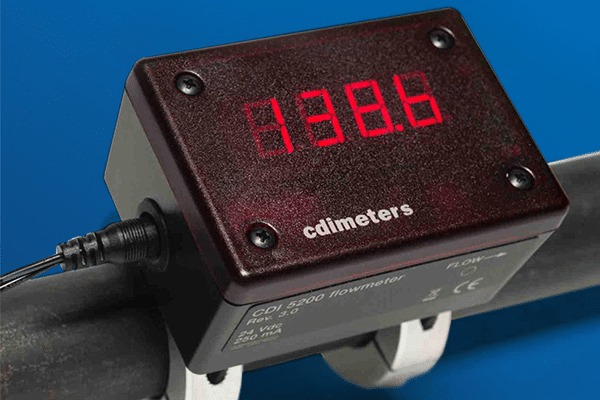

Technology the latest materials combined with smart design allows the flow meter to be installed in a matter of 10-20 minutes by simply drilling two small holes and clamping the unit onto the pipe in an appropriate location. The meter will show instantaneous and accumulated flows.

Now available is a flow meter that can be installed without shutting down known as a hot tap meter. This will allow meters to be installed without shutting down production.

Recording can also be done through an optional flash card and downloaded to a computer plotting program. If you wish you can connect to your computer system through USB port or an RS 485 connection. Any of these allows you to easily see what is going on in your system on a daily, weekly or monthly basis.

If you run a 25 HP compressor 4,000 hours a year paying .10/KW, you will spend approximately $8600 in power. The flow meter with monitoring done a monthly basis can easily save 10% or approximately $860 per year by seeing what is really happening in your air system. The normal ROI is a matter of months.

Give ACW a call at (561) 844-4559 for additional information on these meters, as well as a system review to see where it might be appropriate to install a flow meter in your plant air system.

Contact Us

Contact Us

Palm beach:

1956 W 9th St

Riviera Beach, FL 33404

Monday – Friday 7:30 AM - 4:30 PM

Map and Directions

Miami:

7292 NW 25th St

Doral, FL 33122

Monday – Friday 7:30 AM - 4:30 PM

Map and Directions

Phone Number:

Areas We Serve

- Miami

- Fort Lauderdale

- Hollywood

- Boca Raton

- Stuart

- Vero Beach

- Delray Beach

- West Palm Beach

- Homestead

- Key West

- Fort Pierce