Air Compressor Works

South Florida Boat Manufacturer

South Florida Boat Manufacturer

A major boat manufacturer needed to expand their production facilities by over 50,000 square feet to meet increased client demand; requiring over one mile of new air and vacuum piping. This project required all the utilities to be integrated into the new expansion, including compressed air and vacuum. Both critical for the boat building quality to be maintained.

Their management team wanted one company to provide a turnkey solution that included engineering of the air and vacuum systems, selection of the equipment, and total installation and testing of all the piping. The company selected would also be responsible for the maintenance on 30+ pieces of equipment. Because of the magnitude of this project, the President and VP of operations headed up the management team to review proposals from a number of compressor vendors, including the existing supplier.

The project requirements that were presented were exacting and required a detailed technical review with recommendations to make the job go smoothly.

The key points of the air and vacuum installation project:

-

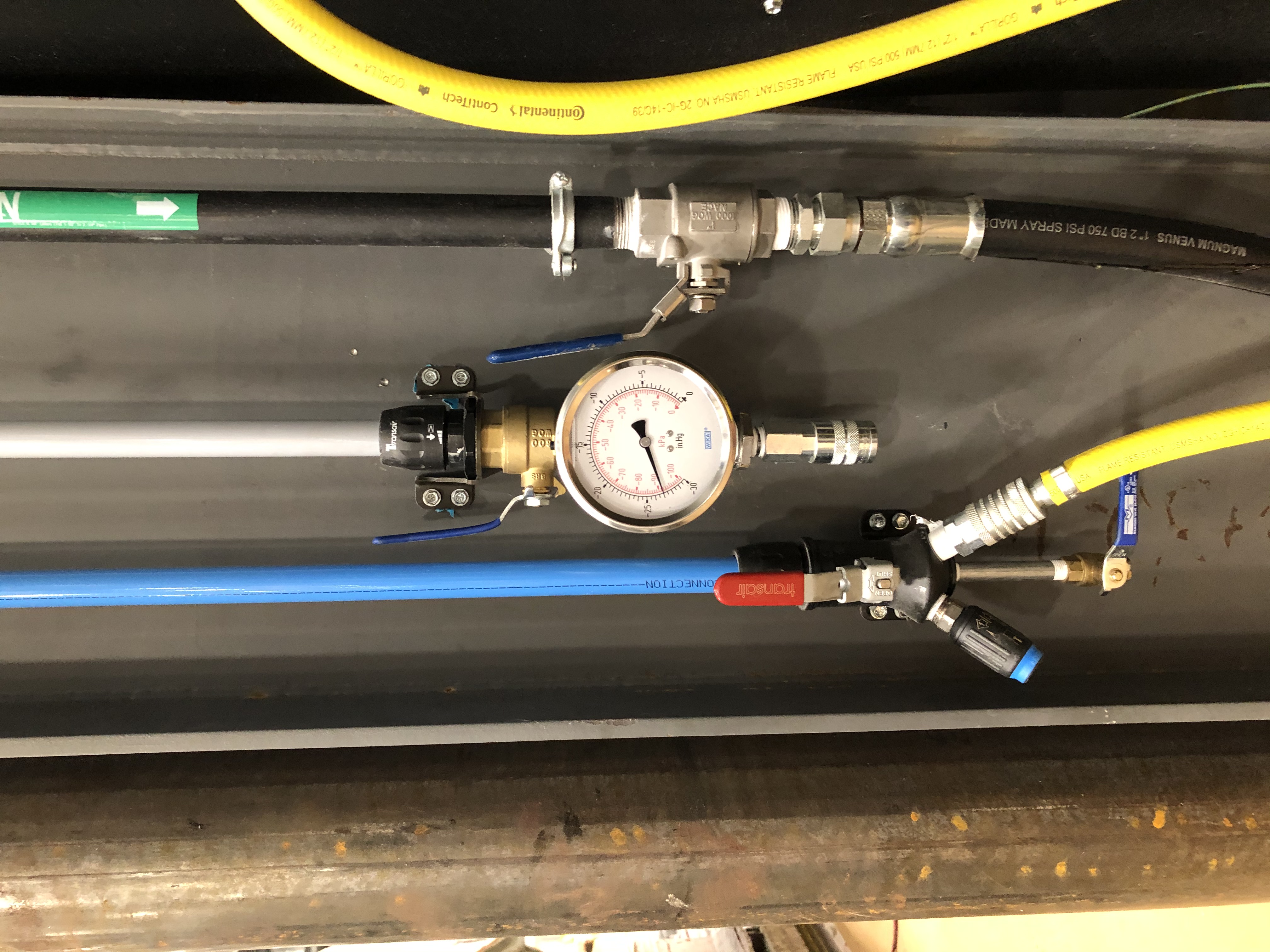

- Piping - Approx. 1 mile of new color-coded air and vacuum lines. (Previously used painted copper and black iron)

- Air Quality - Air system must be absolutely oil-free. Any contamination would ruin the boat construction and finishing process.

- Vacuum - System had to be 100% operational during the molding process. Any loss of vacuum would ruin the large molded boat components in process.

- Installation - 16 week initial window was extremely tight for the air piping.

- Energy Conservation - Review the existing system. Integrate with the new compressor bank and vacuum system for lowest energy use for each production cycle.

- Maintenance - Integrated maintenance plan for existing and new system. Over 30+ pieces of equipment.

After a number of meetings, ACW's engineering and installation team were able to come up with solutions to meet the requirements outlined above.

-

- Piping - Two different colors of powder coated aluminum piping were used to differentiate between compressed air and vacuum. The sales engineer provided samples of all the pipe drop configurations for the client to review. The speed of installation with the aluminum pipe, along with the system fittings, drastically reduced installation costs.

- Air Quality - High flow, low pressure drop three stage filtration with redundant parallel filter banks with oil and water vapor monitor with alarms.

- Vacuum - Multiple 10hp units staged to meet demands based on mold size and provide 100% backup. System monitored and controlled by microprocessor. Emergency supply vacuum tank engineered into the system to maintain vacuum in the event of power loss. Specially designed centrifugal separator installed to prevent any back flow of resin into the vacuum system.

- Installation - Working around the other contractors installing various equipment, while meeting the timeline, was critical to the management team. To expedite the installation process, the compressor and vacuum drops were prefabricated. The Air Compressor Works installation team was ahead of the timeline and worked with the other trades to meet the clients' scheduled production startup.

- Energy Conservation - An air usage study was done on the existing system, then combined with the new production area requirements. It was determined that the compressors currently in use were inefficient, at less than 50% capacity due to inappropriate design and controls. The new system design uses an energy-efficient a 75 HP Kaeser compressor properly staged by using the Kaeser Sigma Air Manager (S.A.M.) This allowed the old 100 HP to be used as a stand by unit for backup. The vacuum system was designed to be a 10 HP multiple unit cascading system run by a PLC control system allowing precise vacuum levels for the varying boat mold sizes. The PLC required additional tuning so the multiple vaccum units would properly respond to the piping/vacuum reciever/separator pot system.

- Maintenance - A condition analysis was done on each of the existing units to determine if it would be used as a regular part of the system or as a backup. The system for the new equipment was then formalized for current and future usage with the lowest energy consumption while maintaining realistic capital expenditure. A detailed maintenance plan was then developed for the 30+ components of the compressed air and vacuum system based on time and use.

Air Compressor Works successfully completed over 1 mile of pipe installation in the new production area. The new piping allowed for a single new Kaeser 75 HP unit to meet the new building's air requirements.

As with any installation and start up, there were bumps in the road. ACW responded to these bumps and ensured that all portions of the system were operating properly. Much appreciation to the president, and his management team, to put their trust in Air Compressor Works to engineer, plan and install an air and vacuum system that is a major utility to produce their quality boats.

Contact Us

Contact Us

Palm beach:

1956 W 9th St

Riviera Beach, FL 33404

Monday – Friday 7:30 AM - 4:30 PM

Map and Directions

Miami:

7292 NW 25th St

Doral, FL 33122

Monday – Friday 7:30 AM - 4:30 PM

Map and Directions

Phone Number:

Areas We Serve

- Miami

- Fort Lauderdale

- Hollywood

- Boca Raton

- Stuart

- Vero Beach

- Delray Beach

- West Palm Beach

- Homestead

- Key West

- Fort Pierce