Air Compressor Works

Combined Services Inc

Combined Services, Inc

Over two years ago an ACW sales engineer Jennifer Viloria made a call on Combined Services in Opa Locka Florida to see how she might be able to assist.

Coincidentally they were looking to improve their air system as the existing compressors were not reliable. Compressed air is critical for their business which has to operate 24/7 as a commercial laundry service for hospitals.

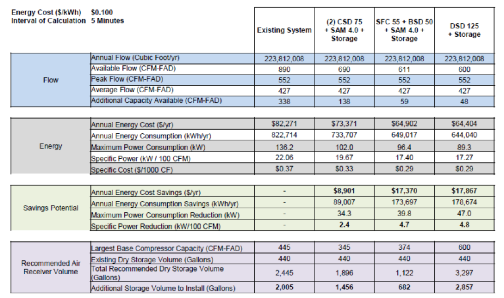

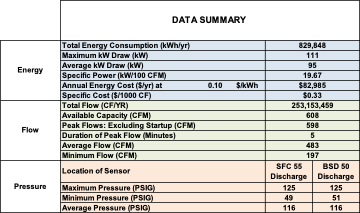

The first step was to see what the real air usage was during the 168-hour week as well as determining actual power cost to operate the compressors. The Kaeser ADA audit system was installed and came up with the following data.

Original System 4/10/18 Power Audit

- 2 each 100 HP Ingersoll-Rand compressors running in tandem with no controls

- ADA Data – .2206 KW per CFM

- ADA Data – 104 PSI

- ADA Data – Average flow 427 CFM

- ADA Data – 822,714 annual KWh ÷ 6000 hours = 137 kWh

Armed with this information the ACW team utilized the ADA report to come up with the following three recommendations for the Combined Services to consider.

The first option, least expensive option, provided the lowest power cost savings of $8901 with 2.4 year Return on Investment (ROI). The second, more expensive, system provided a cost savings of $17,370 but had a 4.7 year ROI. Combined Services was very interested in the second option but was concerned about the investment.

Based on the discussion with the customer the audit information was reviewed by the senior engineer at ACW. He determined that the project might meet Florida Power & Light BCI program requirements for a rebate.

After many hours spent providing engineering data to FPL for the Business Custom Incentive program a rebate of approximately $12,500 was approved bringing the total ROI for the new system down to 2.5 years.

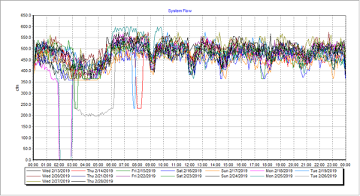

FPL requires a post audit after installation to provide data that the system to prove the power cost savings actually occurred. The graph of the data collected is referenced below along with a summary.

Based on the information above the original system required 822,714 KWH for 427 CFM at 104 PSI. The new system requires 655,233 KW adjusted for increased flow of 483 CFM at 110 psi. This shows an annual savings of 167,481 KWh versus projected savings of 173,697 KWh.

The system provided the savings that it was designed to do and the rebate was paid by FPL directly to Combined Services.

Today Combined Services is enjoying a system with 100% availability which provides over $17,000 in power savings annually.

Contact Us

Contact Us

Palm beach:

1956 W 9th St

Riviera Beach, FL 33404

Monday – Friday 7:30 AM - 4:30 PM

Map and Directions

Miami:

7292 NW 25th St

Doral, FL 33122

Monday – Friday 7:30 AM - 4:30 PM

Map and Directions

Phone Number:

Areas We Serve

- Miami

- Fort Lauderdale

- Hollywood

- Boca Raton

- Stuart

- Vero Beach

- Delray Beach

- West Palm Beach

- Homestead

- Key West

- Fort Pierce