Air Compressor Works

Post

Guide for a Healthy Compressed Air System

September 19, 2022

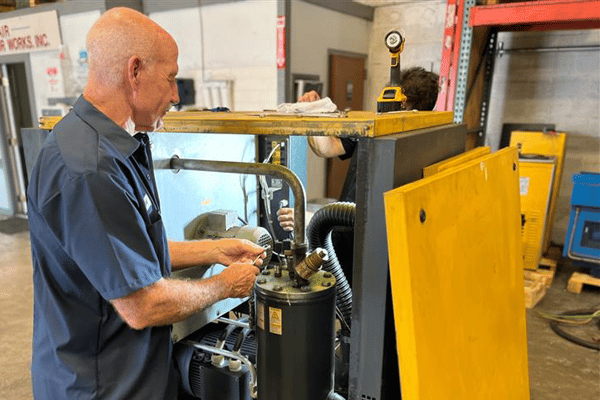

Air compressors can serve a wide variety of purposes, whether for industrial, small business, or personal needs. With many moving parts and intricacies, it’s important to remember that “cheap is expensive” – if you try to cut costs and avoid routine maintenance, you’ll pay for it later. This guide easily explains quick and effective tips to maintain a healthy compressed air system.

Regular maintenance for your compressed air system helps to eliminate future issues, saving you or your business time and money in the long run. Further, it’s important to stay proactive and take care of issues before they arrive. Why deal with the stress of a problem when you can help prevent it?

Tip #1 | Change Air Filter

To no surprise, air is one of the most important factors in your compressed air system, so it’s incredibly important to keep your air intake as clean as possible. Much like our noses filter the air entering our lungs, and air conditioner filters remove dust and debris, your air compressor filter acts as a gateway between dirty and clean by protecting against dust, aerosols, and oil vapors. You wouldn’t want to breathe in contaminated air, so why should your air compressor have to?

On top of this, a dirty air filter means that your compressor will need to work harder (and therefore use more energy) to work properly and achieve your desired results. This translates into higher electricity costs, which can grow quickly over time if you don’t keep your system in check.

If your air filter is dirty or appears to be clogged, don’t hesitate to replace it. Depending on the manufacturer of your compressor, you may be able to wash it (make sure to read the manual or contact us if you have any questions).

Tip #2 | Check Hoses and Look for Leaks

In compressed air systems, air is moving rapidly from one place to another at extremely high pressure. Sometimes, leaks are inevitable, but you can work to greatly reduce the rate at which they occur.

If leaks go unnoticed in your system, your compressor has to compensate by working harder, which also contributes to higher electricity costs.

To check for leaks, take a careful review of joints, connections, and hoses in your system. Sometimes, hoses can crack or corrode due to improper maintenance. Try to avoid bending or kinking hoses, which can disrupt the flow and affect pressure.

Tip #3 | Change Oil Filter

Similar to how air filters remove unwanted particles, your system’s oil filter plays a crucial role in ensuring dirt, sand, pieces of rust, and other unwanted debris remains out of your compressor. A clogged filter can result in an overworked compressed air system, which is yet another contributing factor to unwanted electricity costs. Plus, it could also lead to unnecessary heat.

Depending on the brand, size, and type of compressor you have, you should aim to change your oil filter at regular intervals between 2,000 and 4,000 hours. Consult the manufacturer or manual to find the exact number.

Still uncertain of when you should swap out an old oil filter? Ask us!

Tip #4 | Check Oil and Lubricant Levels

Would you drive your car if it’s in urgent need of an oil change? In your compressor system, oil and lubricants keep everything running smoothly and efficiently. If your oil levels are low, you can ruin your system and incur hefty repair or replacements costs.

Heat is a major component in determining how long oil lasts in your compressed air system. “Oil life” refers to the duration that oil lasts within your system. If you notice that your compressor’s oil life is dwindling or is significantly lower than the industry average, it could be a result of excess heat or another issue.

When adding oil, make sure to fill it up to the fill line – do not exceed it! When pouring, be careful not to spill any oil onto the exterior of your compressor. Note that not all oil is the same. Most oils and lubricants are developed for their respective brand of compressors, so make sure you’re giving your system the appropriate one.

Tip #5 | Replace Separator Element

In simple terms, the oil separator separates oil and air. Since compressed air needs to exit the compressor free of oil, the health of the oil separator is very important. Because of this element, the excessive use of oil is prevented, as it’s cycled right back into the system.

Without proper maintenance of your system’s oil separator, your energy costs will inevitably rise, so keeping this element in good shape is essential to maintaining the overall health of your system.

Sustaining a Healthy Compressed Air System

Remember, it’s always more effective to be prepared than to deal with issues as they arise. By keeping your air system maintained, you can expect the best and ensure that your business stays up and running at all times and isn’t plagued with bouts of downtime due to poor maintenance. Make sure to utilize resources (like this guide) to stay on top of your compressed air system to keep it healthy!

Are you located in South Florida? Learn more about our Preventative Maintenance services and programs for your system, as well as our Rental options.

Contact Us

Contact Us

Palm beach:

1956 W 9th St

Riviera Beach, FL 33404

Monday – Friday 7:30 AM - 4:30 PM

Map and Directions

Miami:

7292 NW 25th St

Doral, FL 33122

Monday – Friday 7:30 AM - 4:30 PM

Map and Directions

Phone Number:

Areas We Serve

- Miami

- Fort Lauderdale

- Hollywood

- Boca Raton

- Stuart

- Vero Beach

- Delray Beach

- West Palm Beach

- Homestead

- Key West

- Fort Pierce