Air Compressor Works

Post

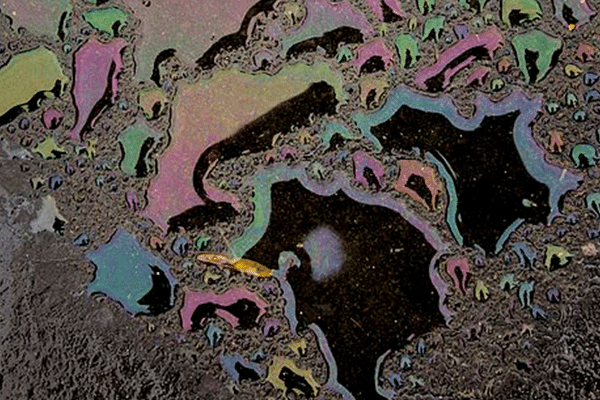

Oil and Water Don’t Mix

December 21, 2020

Your air compressor makes water every day. Water is unavoidable in a compressed air system.

Think about it: When you are compressing 7 cubic feet of atmospheric air into 1 cubic foot inside the compressor, the air now contains seven times as much moisture as what existed in the atmosphere. The cubic foot of compressed air in the system is at 100 percent humidity at 190° Fahrenheit or above. When the temperature goes below 190° F in the separators/filters/dryer it starts to rain oil and water, which is called condensate. The key is how to dispose of condensate legally and to be conscious of our environment.

How much condensate does your system really make? Here are 2 examples.

- Winter Conditions – A 200 CFM compressor at 70F inlet air with 50% relative humidity makes three-quarters of a gallon of condensate per hour, or 60 gallons per week in a 2-shift operation.

- Summer Conditions – A 200 CFM compressor at 85F inlet air with 80% relative humidity makes two gallons of condensate per hour, or 160 gallons per week in a 2-shift operation.

To calculate how much condensate your systems makes, Kaeser has a great tool.

Water condenses out of the airstream in the system as it flows through the wet tank, pre-filter, refrigerated dryer and after-filter. These components remove approximately 95% of the moisture in the system when everything is operating properly.

The remaining water vapor that is condensed inside the compressor is not the real issue. It’s the oil that is carried along with this condensate. The compressor’s lubrication oil contaminates the water being removed and creates hazardous waste that cannot be discharged to ground or most waste removal systems.

The question then becomes: how do you deal with the oily condensate as it is collected from the drains each of these components?

Here are four ways to deal with compressor condensate to keep your company legal and green:

- Collect your condensate in a safe container for collection by a licensed waste disposal firm. This process will eliminate any potential issues but can be very expensive with disposal costs being upwards of $100 per drum.

- Mechanical separators with carbon filters are very effective on most compressor oils. They create a clear water discharge using carbon filtration and separate the condensed oil to be disposed of properly. Some synthetic silicone or glycol-based compressor oils need to be tested for separation to be sure that a unit will work properly. The key to a system of this type operating smoothly is quarterly maintenance of the filters and separation devices to ensure the water is clear going to drain. The initial investment is realistic with annual maintenance costing approximately 10% of the purchase price.

- Condensate boil off units are often used in medium and large firms, and they operate much like maple syrup makers. The condensate is collected in a unit and then heated. As the water is boiled off, the oil residue is left behind for proper disposal. Units work on any lubricant and can be powered by either gas or electricity. The investment is realistic and depends on the cost of gas or electricity. Operating costs can vary, but it’s typically between 15-20% of initial investment.

- Central collection systems. Many large plants have a central collection system for waste materials, including machining fluids and other cooling media, that also can be used for condensate disposal. A test is recommended by putting a sample of condensate into the system to see if it is properly treated. The costs of collection and transportation inside a large facility may be too high, requiring individual treatment units in each compressor rooms.

In a few unique cases, condensate has been allowed to go to a town or city sewer depending on lubricant in use as well as ratio of condensate to total discharge and the approval of the local authority.

Oily condensate is an unpleasant fact regardless of temperature and humidity and must be handled properly by all companies to be legal and to protect our environment.

We stand ready to assist to work with you on your condensate requirements, however big or small.

For more information, contact Sales Team by email or (800) 345-4364

Related Post

Contact Us

Contact Us

Palm beach:

1956 W 9th St

Riviera Beach, FL 33404

Monday – Friday 7:30 AM - 4:30 PM

Map and Directions

Miami:

7292 NW 25th St

Doral, FL 33122

Monday – Friday 7:30 AM - 4:30 PM

Map and Directions

Phone Number:

Areas We Serve

- Miami

- Fort Lauderdale

- Hollywood

- Boca Raton

- Stuart

- Vero Beach

- Delray Beach

- West Palm Beach

- Homestead

- Key West

- Fort Pierce